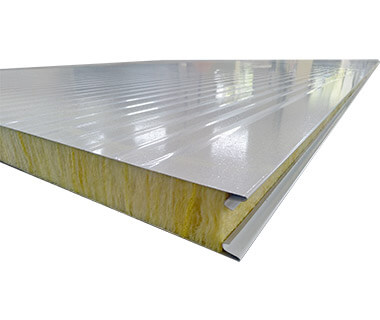

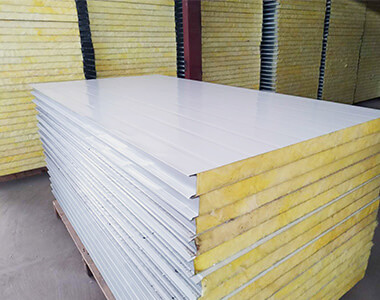

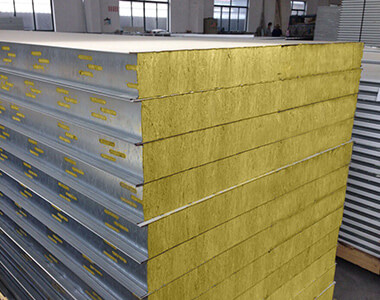

Rock wool

Feature:

1)Friendly environmental :Made from natural, sustainable material.Typically contains up to 75 percent recycled content.

2)Great heat retainer & sound-deadening : it doesn't allow heat to transfer through it very easily.

3)Fire resistan:Non-combustible and fire resistant to about 1,400 degrees,which is greater than glass wool.

4)Highly water repellent :Any bulk water that contacts the outer surface will drain and not be absorbed into the body of the insulation.

5)Long-term performance :rock wool doesn’t degrade over time and allows moisture to escape ,which deters mold and mildew.