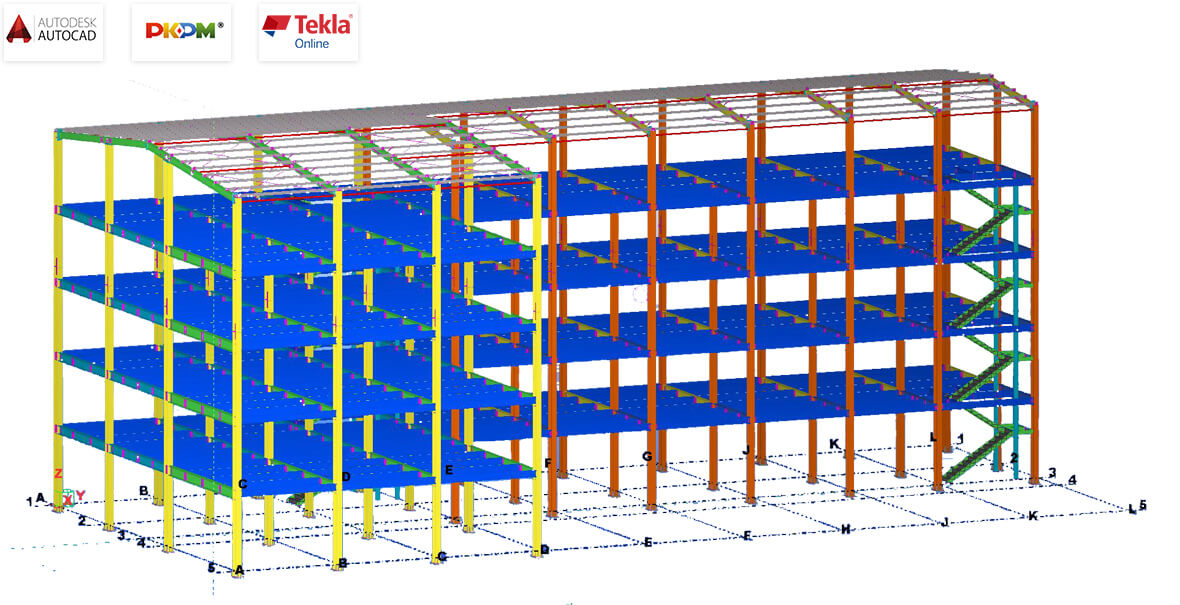

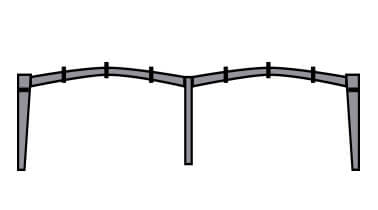

Multi-span low consruction

Applyable for: office, grocery and any kinds of store.

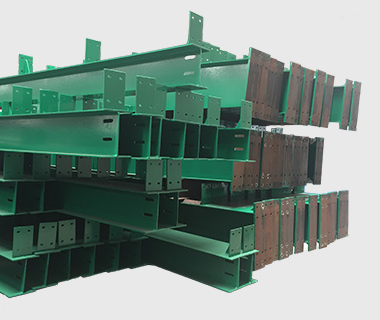

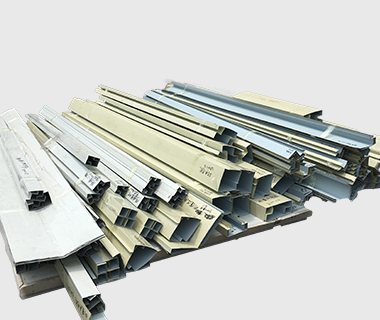

The structure It adopts H type steel, C type steel and Z type steel to combine or build the framework while employing the compressed color corrugated steel sheet or color steel sandwich panels for its walls and roof. Now the steel structure building has basically substituted traditional reinforced concrete one in developed countries. It possesses many excellent characteristics such as large span, few materials, low cost, no base, short building cycle, reliability and safety, beautiful appearance etc. It is widely used in buildings like monolayer workshop, storage house, commercial architecture, office block, multi-layered park and residential house etc.

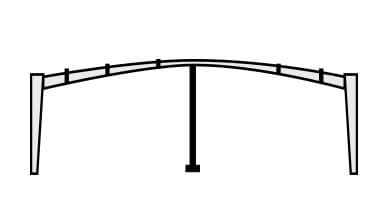

Large-span building, suitable for large-area buildings such as factories and warehouses

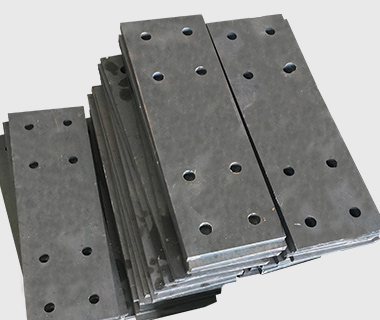

Prefabricated products, fully bolted, eliminating a lot of cumbersome processes and labor

Cost-effective, fast installation

Service life >30 years

Based on steel structure and screw connection, the overall flexibility is good, and it can withstand earthquakes of magnitude 7-8

The overall safety performance of the structure is good, and it can withstand winds of 120km/H or more

Building materials can be reused to reduce construction waste environmental pollution

The highest number of layers can be built into 5 layers

Applyable for: office, grocery and any kinds of store.

Applyable for: warehouse, sales center, factory or other constructions needed large area of high eave.

Applyable for: indstrial large span workshop(with crane), gymnasium, warehouse etc.

Applyable for: factory or factory's continuation.

Applyable for: warehouse, sales center, factory or other constructions needed large area of high eave.

Applyable for: additional construction, tool room, outside of the construction, expublic place of the storage.

Pre-embedded parts are needed in the first step of building a good foundation.

If the project belongs to a multi-storey building, pre-Piling is required.

We will provide corresponding drafts of foundation according to different projects.

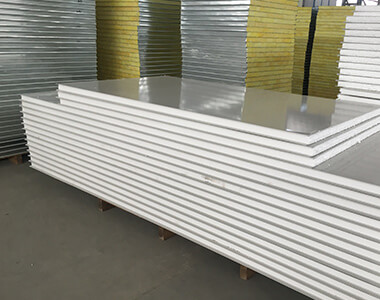

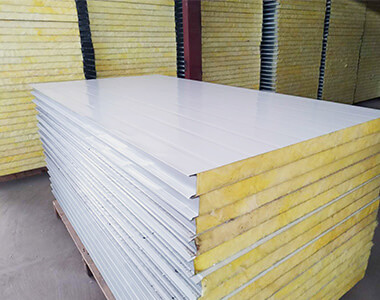

1)Density:6/7/8/9/10/12kg/m³.

2)Thickness: 50mm/75mm/100mm.

3)Roof panel's size: Length * 1050 * thickness.

4)Wall panel's size: Length * 1150 * thickness.

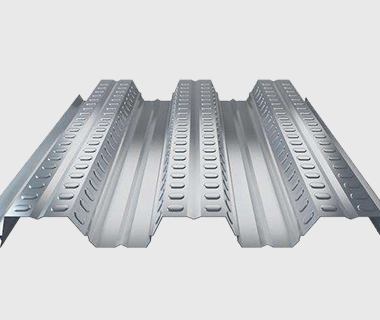

Corrugated steel sheet, 840#is for the roof,900# is for the wall.

1)Thickness: 0.376mm/0.426mm/0.476mm.

2)Size:same as the above.

1)Lightweight.

2)Not friendly environmental.

3)Goodsound insulation :It's a great material for keeping noise from entering your home.

4)Low water absorption :EPS is resistant to moisture.

5)Non-fire resistant:EPS is flammable, as is the case with so many other building materials. However, this is only relevant if you assess EPS as an exposed insulating material.

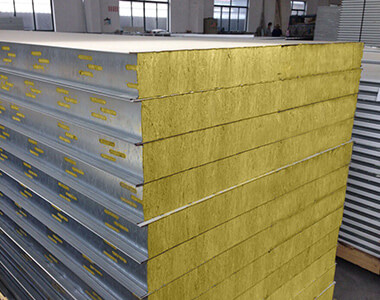

1)Density:40kg/m³.

2)Thickness : 50mm/75mm/100mm.

3)Roof panel's size: Length * 960 * thickness.

4)Wall panel's size: Length * (1150/950) * thickness.

Corrugated steel sheet, 840#is for the roof,900# is for the wall.

1)Thickness: 0.376mm/0.426mm/0.476mm.

2)Size:same as the above.

1)Friendly environmental :glass wool generally have lower environmental impacts than foam plastic insulation materials

2)Optional heat retainer & sound-deadening :Retains heat well and traps air, which slows the transfer of heat and sound.

3)Fire resistance :Glass wool is non-combustible as mineral wool. However ,mineral wool has far better fire resistant qualities than glss wool.

4)Bad water repellent : Wet insulation in a closed wall cavity will usually not rapidly dry out.However, if it can dry out and has not become compacted, it will retain its insulating properties.

1)Density: 60/80/100/120kg/m³

2)Thickness: 50mm/75mm/100mm.

3)Roof panel's size: Length * 960 * thickness.

4)Wall panel's size: Length * (1150/950) * thickness.

Corrugated steel sheet, 840#is for the roof,900# is for the wall.

1)Thickness: 0.376mm/0.426mm/0.476mm.

2)Size:same as the above.

1)Friendly environmental :Made from natural, sustainable material.Typically contains up to 75 percent recycled content.

2)Great heat retainer & sound-deadening : it doesn't allow heat to transfer through it very easily.

3)Fire resistan:Non-combustible and fire resistant to about 1,400 degrees,which is greater than glass wool.

4)Highly water repellent :Any bulk water that contacts the outer surface will drain and not be absorbed into the body of the insulation.

5)Long-term performance :rock wool doesn’t degrade over time and allows moisture to escape ,which deters mold and mildew.

Project located : Republic of Senegal/Sizes: 60m *100m*7m/Total building area: 6000sqm/Application: Workshop factory

Mar, 2016:We met

July, 2016:Our technology and trade manager went to Senegal for meeting

Feb, 2017:Received advance payment

Jun, 2017:Finished project production

Sep, 2017:Installation team(3 people) departure time

Jan, 2018:Installation team(3 people) came back time

Issue:Stop proceed 4 months since the exchange rate problem

Structure: H-shape steel beam+C shape steel purlin

Color: customized

Material: Q345B H shape steel structure +EPS sandwich panel

Manufacturing time: February, 2017-June ,2017

Delivery time: June, 2017

Your installation team are hard-working to work with us. Your explained everything. I really appreciate dealing with an honest and efficiency steel company.

We usually respond within 12 hours, or faster.